The Essential Steps for Successful Setup of HDPE Pipeline in Your Following Job

Effective setup of HDPE pipe needs cautious preparation and implementation. Trick steps consist of evaluating project demands, preparing the website, and choosing correct joining techniques. Each phase plays a crucial duty in making sure the stability and efficiency of the pipeline. Comprehending these vital actions can substantially affect the general success of the project - hdpe pipe suppliers Midland TX. Nevertheless, the nuances of each step might hold the secret to getting rid of typical difficulties faced throughout setup

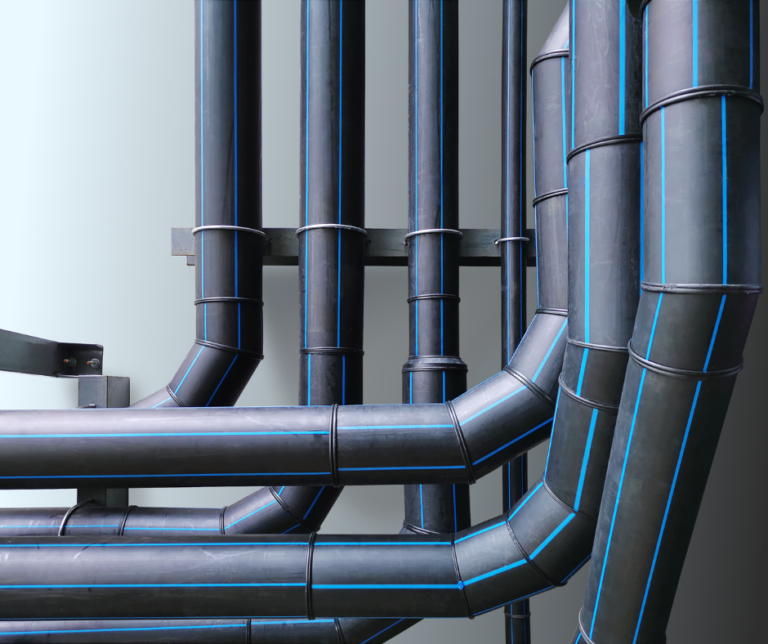

Recognizing the Conveniences of HDPE Pipe

High-density polyethylene (HDPE) pipeline uses various advantages that make it a recommended option for various applications. Its high resistance to rust and chemicals guarantees longevity popular environments, substantially prolonging the life-span of installments. Furthermore, HDPE's adaptability permits easier setup, specifically in challenging terrains, as it can bend without damaging. The light-weight nature of HDPE pipeline simplifies transport and handling, minimizing labor costs throughout installment.

HDPE pipeline is recognized for its low friction coefficient, which improves liquid circulation and reduces power usage. Its smooth construction lowers the risk of leaks, adding to far better source administration and ecological protection. In addition, HDPE is recyclable, lining up with sustainable methods and decreasing environmental effect. Generally, the mix of stamina, flexibility, and eco-friendliness makes HDPE pipe a premium choice for a wide variety of projects, from water distribution to industrial applications.

Preparation Your HDPE Pipeline Installment

When preparing an installment of HDPE pipeline, cautious consideration of several key aspects is essential to protect a successful project. Task managers should assess the specific needs of the pipe, including the planned usage, circulation rates, and environmental problems. Comprehending these parameters will lead the choice of suitable pipeline dimensions and material grade.

Next off, timelines ought to be established, considering procurement timetables and any type of potential hold-ups. Sychronisation with local authorities for authorizations and regulative conformity is likewise crucial. Furthermore, a comprehensive spending plan ought to be prepared, incorporating all expenses linked with materials, labor, and equipment.

It is crucial to engage a certified group experienced in HDPE pipe setup. Their experience will assist reduce threats, guarantee adherence to market criteria, and eventually add to the task's success. Complete preparation prepares for a smooth installment procedure and long-lasting performance of the HDPE piping system.

Preparing the Site for Installment

Correct site preparation is crucial for the successful installation of HDPE pipeline. Prior to setup starts, the website must be completely assessed to guarantee it satisfies all needed demands. This consists of evaluating the ground for existing frameworks, energies, and possible hazards that could impede the setup process.

Correct elevation and alignment must be developed to preserve a constant slope for water drainage objectives. Correct drainage around the installation website is also critical to avoid water build-up, which can cause difficulties down the line.

Strategies for Joining HDPE Water Lines

Achieving a trustworthy link between HDPE pipes is vital for ensuring the integrity and longevity of the installment. Numerous strategies exist for signing up with these pipes, each matched for various job demands. Fusion welding is one of one of the most common methods, making use of warm to bond the pipe finishes with each other, producing a seamless and sturdy link. This technique can be further classified into outlet combination and butt fusion, relying on the pipe configurations.

Mechanical installations are one more option, using clamps and threaded adapters to join areas of HDPE pipe. While generally faster to mount, they may call for added maintenance over time. Electrofusion is a specific method that entails utilizing electrical existing to warm and fuse the pipes with specially created fittings, making sure a strong bond. Choosing the appropriate signing up with technique is critical, as it directly influences the overall performance and integrity of the HDPE piping system in the intended application.

Evaluating and Inspection of Installed Water Lines

The screening and evaluation of set up HDPE pipelines are essential to guaranteeing their capability and long life. This procedure includes visual assessment methods, pressure testing techniques, and leak detection procedures to determine possible concerns. By using these methods, experts can verify the honesty of the installment prior to it is placed into usage.

Aesthetic Inspection Techniques

Employing effective aesthetic examination strategies is vital for assuring the integrity of set up HDPE pipelines. Examiners must methodically check out all noticeable sections of the pipeline to identify any signs of damages, imbalance, or improper installation. Key indicators to assess consist of joint integrity, surface irregularities, and links. Assessors may use tools such as amplifying glasses or cams to improve visibility and detail. It is important to inspect for indications of environmental stress, such as buckling or too much bending, which could jeopardize performance. Consistent documentation of searchings for enables for tracking changes in time and helps guide essential fixings. By adhering to established aesthetic assessment methods, project groups can significantly reduce the threat of future failures and guarantee long-lasting reliability of the piping system.

Stress Evaluating Approaches

Visual inspection offers as a preliminary action, yet it is not sufficient on its very own to guarantee the efficiency of installed HDPE pipelines. Stress testing approaches are essential for guaranteeing the stability of these systems. Generally, hydrostatic screening is used, where the pipes are loaded with water and subjected to pressure levels over the intended operating pressure. This approach helps determine weak points or potential leaks. Pneumatically-driven screening can also be used, although it brings better threats because of the compressibility of air. No matter the method chosen, adhering to sector criteria and safety procedures is crucial. After conducting pressure tests, comprehensive documents is necessary to validate the results and verify that the setup fulfills all functional requirements before proceeding to the next stage of the task.

Leak Detection Procedures

How can one guarantee that installed HDPE pipes are without leaks? Effective leak discovery procedures are crucial to protect the integrity of the system. Initially, aesthetic examinations ought to be carried out, looking for signs of water buildup or dirt erosion around pipe joints. Following this, pressure screening can verify the system's strength. A common approach is the hydrostatic examination, where water is introduced under stress, monitoring for decreases that indicate potential leakages. Furthermore, progressed modern technologies, such as acoustic sensors or infrared thermography, can spot leakages that might not be visible. Routine monitoring and upkeep further add to the durability of HDPE pipelines, guaranteeing they remain leak-free throughout their functional lifespan. Appropriate documentation of these procedures is crucial for compliance and future referral.

Maintenance Tips for Long-Term Efficiency

To assure the longevity of HDPE pipes, developing a normal evaluation timetable is important. This aggressive technique enables the early discovery of possible issues, decreasing pricey repair work. Additionally, executing proper cleaning techniques will aid maintain peak performance and stop build-up that can impact performance.

Normal Inspection Schedule

HDPE pipelines are recognized for their durability and resistance to corrosion, developing a normal examination timetable is crucial for guaranteeing their lasting performance. Routine assessments assist determine prospective issues such as leakages, joint honesty, and ecological effects that may affect the pipe's capability. It is suggested that examinations occur a minimum of biannually, or extra often in atmospheres with extreme conditions. American Plastics HDPE Pipe for Oilfield. During these analyses, visual checks need to be performed to detect signs of wear or damage. In addition, using modern technology such as ultrasonic screening can give additional understandings right into the pipeline's condition. By implementing an organized evaluation try here schedule, task supervisors can proactively attend to problems, consequently extending the life-span of HDPE pipes and maintaining system performance

Appropriate Cleansing Techniques

Appropriate cleansing methods play a crucial function in maintaining the long-lasting efficiency of HDPE pipes. Routine cleansing stops the accumulation of particles, sediment, and biofilm, which can result in clogs and decreased flow performance. Operators ought to utilize approaches such as high-pressure water jetting or foam cleaning to successfully eliminate impurities without damaging the pipeline surface area. It is vital read this to prevent utilizing rough chemicals that might break down HDPE product. Additionally, scheduled maintenance checks should include visual inspections for any signs of wear or damage. Correctly educated employees need to carry out these cleaning processes, making sure conformity with safety and environmental regulations. By implementing these practices, the lifespan of HDPE pipelines can be greatly extended, ensuring optimal performance throughout their operational life.

Often Asked Inquiries

What Are the Environmental Impacts of HDPE Pipe Manufacturing?

The ecological influences of HDPE pipe manufacturing include greenhouse gas discharges, energy consumption during manufacturing, potential plastic pollution, and challenges in reusing. HDPE's durability and resistance to corrosion can mitigate some ecological problems.

Just How Does HDPE Pipe Contrast to Various Other Materials?

What Equipment Are Essential for HDPE Pipeline Setup?

Vital tools for HDPE pipe setup consist of a combination machine, pipe cutters, shovels, gauging tape, and safety gear. Correct devices warranties reliable, safe handling and setup, adding to the task's total success and integrity.

Are There Any Type Of Details Rules for HDPE Pipe Installation?

Details regulations for HDPE pipe installation vary by region, usually controlled by regional, state, or federal codes. Compliance with these laws guarantees safety, environmental defense, and functionality, making adherence important for successful project end results.

Can HDPE Pipeline Be Recycled After Use?

Yes, HDPE pipelines can be reused after usage. Their polycarbonate nature permits reprocessing, making them ideal for recycling into new products. This sustainability aspect adds to drain pipe inspection camera ecological preservation and promotes circular economic situation techniques in construction.